The main thing you need to make your industrial business successful is great employees. Whether your business manufactures products or fabricates metal, keeping team members safe should be a top priority. Each year, millions of employees are injured in workplace accidents. In many cases, these accidents are preventable.

Creating a safer workplace for your team is a great way to reduce these accidents and improve morale. If employees see that you are working hard on their behalf, they will be more likely to stay with your company for the long haul. Are you attempting to make your industrial workplace safer for employees? If so, here are some things you need to consider.

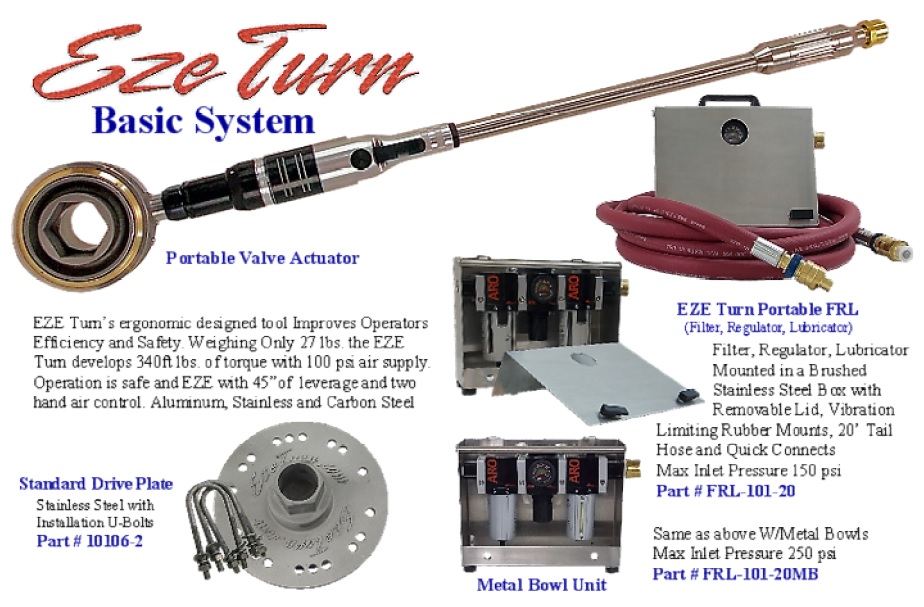

The Right Equipment Can Create a Safe Work Environment

The use of outdated tools can be extremely dangerous in an industrial work environment. If employees have to handle difficult tasks like turning large valves by hand, it is only a matter of time before problems occur. These valves typically require a lot of force to open them. Requiring employees to perform this difficult task by hand can lead to such injuries as:

- Ruptured disks

- Heatstroke

- Back strain

- Pinched nerves

- Extreme fatigue

If you want to make operating these valves easier for your team, then investing in the EZE Turn Basic PVA System is a must. This portable vale actuator makes opening and closing valves much easier and safer. With the addition of this tool, you can make life easier for your hard-working employees.

If you do buy or rent one of these systems, be sure to invest in one of the on-site storage cabinets offered by the team at EZE Turn to keep it protected. With this storage cabinet, you can keep your EZE Turn Basic PVA system protected from the elements and the damage they can cause.

Provide Your Team with Personal Protective Equipment

The typical industrial manufacturing facility has a variety of different hazards. One of the best ways to keep employees safe in this environment is by providing high-quality personal protective equipment (PPE). This equipment should include things like safety glasses, hardhats and respirators. If you have forklift trucks operating in your warehouse, then safety vests are also a good idea. These vests will make pedestrians more visible to forklift operators, which can help prevent accidents.

Employee Training is Crucial

Assuming new employees know how to mitigate the risks associated with working in an industrial manufacturing environment is foolish. Employees that don’t receive proper training are at a higher risk of being injured on the job. Rather than allowing this to happen, you need to take employee training seriously. By properly training team members, you can make them aware of the dangers around them and how to avoid getting hurt. Ongoing training is also crucial when adding new machinery to the workplace.

By putting the tips in this article to use, you should have no problem keeping the employees working for your company safe and engaged.